25 May 2024

A guide to storing silage and managing effluent collection

After a long winter farmers are replenishing silage stocks. Storage capacity, silage quality, effluent management and safety are all vital considerations. Tom Fallon, Teagasc Farm Buildings & Infrastructure Specialist, tells us more.

Silage pits that are excessively high pose a safety risk to you, family members, employees and contractors. They are more difficult to manage and there is invariably more waste silage with such pits because it is hard to adequately consolidate the grass and keep air out. To help minimise losses always cover silage with two or more sheets of 500 gauge polythene. Pits should be regularly inspected so that any flapping, damage from birds, cats etc. can be repaired. A net over the tyres will help.

Measuring a silage pit

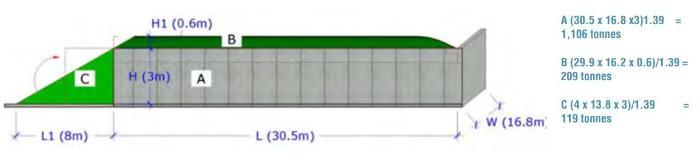

The best way of measuring a silage pit is to break it into sections as shown in the diagram below, for a pit with three walls (one is hidden). It’s the number of tonnes of settled silage you want to establish so wait at least four weeks after ensiling. The typical density of pit silage of approximately 25% dry matter is one tonne per 1.39 cubic metres (49 cubic feet). It is recommended that the pit above the wall slopes in at 45 degrees; this will reduce the risk of the loader slipping. It will also prevent pressure beyond that which the wall is designed to carry. To achieve a 45 degree angle, for every metre of a rise the side has to come in by a metre. In this case, to calculate the silage in section B we deduct 0.6m from both the length and width. In section C there will be a wedge of silage on each side. So again we reduce the width by the height (on the ground you would measure from half way up one side to half way up the other side to get an average width).

In the diagram, for simplicity, we assume the front of the pit is a neat triangle. In reality this section might start at 0.8m rising to 3m. If that is the case you would use an average height of 1.9m for this section by its full length. Ideally a pit should be filled from one end and emptied from the opposite (high) end, to make it easier to pull back the covers and to keep rainfall away from the pit face.

How high is safe?

In the past silage pits were about 12m (40 feet) wide with walls of about 2.1m (7 feet). With large herds we can justify going to 3m high walls and pits 15.2 to 18.3m (50 to 60 feet) wide. A target height of up to 3.6m (12 feet) of settled silage is reasonable. At ensiling the pit will be one to two metres higher. You will get better value from your walls if your pit is reasonably wide. The pit in the diagram would suit a 200 cow herd. At an intake of 40 kg silage per cow per day, the herd would consume 56 tonnes per week. The recommendation is to use at least a shear grab depth (typically 0.9m) of the face each week which in this case is 39 tonnes so almost 1.5 times the pit face will be used each week.

Chop length

Precision chop harvesters cut grass to an average length of about 5cm. Wagon-cut silage will be somewhat longer. Finely chopped grass does not bind well. This means that the sides of silage clamps cannot be too steep. The same applies when piling grass above silage pit walls. Pits slipping during or shortly after silage making is related to the dry matter of the silage, the speed of filling the pit and possibly how easy it is for effluent to escape (presence of channels). Wilting grass to about 30% dry matter will reduce the risk of the pit slipping. It is important that the grass in the pit is rolled in layers of about 15cm so that there is a consistent density throughout the pit. A spongy silage pit is not stable in more ways than one Most farmers now aim to make reasonably dry silage. If this is not possible and your silage is likely to be 25% dry matter or less it would be worthwhile talking to the contractor about increasing the chop length to 8cm.

Effluent collection and storage

A silage clamp (i.e. no walls) is required to have a channel on all four sides. The silage cannot extend beyond the boundary of these channels. Place a perforated pipe in these channels to facilitate effluent flow and to reduce the possibility of stepping into a channel and twisting an ankle etc. Any grass lying on the pipe/channel needs to be removed before covering the pit. The plastic covering the pit should extend out over the channel so that there is no unnecessary collection of rainwater. Many farmers store silage effluent in slurry tanks. On some farms there is a dedicated tank for storing silage effluent. This tank needs to have a capacity of 7m3 per 100 tonnes of silage and a vacuum tanker has to be available for emptying.

Effluent is largely generated in the six weeks after ensiling. It is essential that effluent is collected from silage pits right up to when silage feeding commences in the following autumn/winter. Runoff from open silage pits can be classified as soiled water and county councils may require partial or full collection unless the silage pit is kept clean. Check the silage effluent collection facility from the pit all the way to the storage tank. Ensure that the pit channels and pipework are clear, that any manholes are properly set up and that there is always adequate spare capacity in the tank especially if you are going away for a weekend etc.

This article first appeared in the May/June issue of Today’s Farm. Read more from Todays Farm