Calf Housing

Calf housing (PDF)

Providing the correct housing environment is central for a calf to perform during the rearing period and to avoid stress and other health issues.

Ventilation

- Natural ventilation is the most efficient and least expensive method of providing an optimum environment.

- Ventilation is predominately provided by a combination of wind and stack effect in Ireland.

- Eliminates noxious odours, draughts and stagnant air, while also providing fresh air.

- Crucial to maintain environmental humidity levels and to decrease airborne dust, endotoxin levels and pathogens.

- Must serve to maintain temperatures within 15- 20°C – calf performance maximised.

- At least five or six air changes per hour required within a calf shed.

- At least 7m³/calf of total air capacity should be provided to young calves; 10m³/calf required by two months old.

- Long, narrow sheds are easier ventilated than wide, square houses. Width should not exceed 11m.

- A calf shed should be stand-alone, located up wind of other cattle housing facilities and at right angles to the prevailing wind.

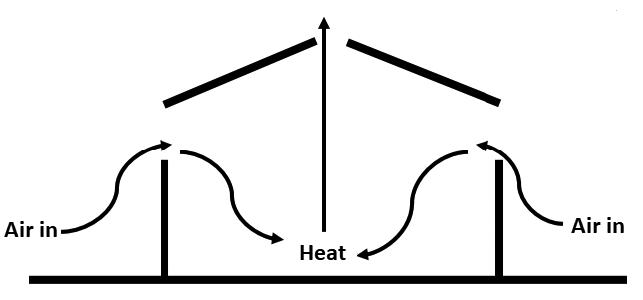

The Stack Effect

- The stack effect is the same principle by which smoke is drawn up a chimney.

- Air inlets and outlets are required.

- Air heated by livestock rises, escapes through the outlet area (highest point of the shed) and is replaced by fresh air through the inlet area.

- The inlet needs to be two to four times the area of the outlet.

- An outlet of 0.04m²/calf is desired.

- Yorkshire boarding is preferred over space boarding or vented sheet as an inlet; it supplies draught-free air without allowing rain in.

- Effective air outlets include a simple ridge outlet, ridge upstands or ridge capping.

Figure 1: Stack effect

Drainage and Dry Bedding

- Calves can spend 80% of their time lying down; the type and depth of bedding is important.

- Deep beds of straw are an effective way of protecting calves from the cold.

- Avoid damp bedding; it facilitates the survival and spread of bugs and reduces temperature.

- Use the ‘knee test’ to determine the dryness of bedding.

- Flooring should facilitate the easy cleaning and removal of excess moisture from the shed.

- A 1:20 floor slope is recommended.

- Waste channels are required to carry excess liquid out of shed to an external storage point.

Hygiene and Cleaning

- Hygiene is critical; calves are most vulnerable to pathogens and disease during the rearing period.

- Easily-cleaned floors and walls are required to permit the deep cleaning and disinfection of pens between batches of calves.

- Once cleaned out and disinfected, a long rest period is an effective means of ensuring that bugs are eliminated from the calf house.

- The use of water should be kept to a minimum when calves are present in the shed.

Other Considerations

- Clean water must be available to calves at all times.

- Contamination of feed and water from other calves, vermin and flies should be avoided.

- The correct feeder and drinking space must be provided to encourage feed and water intake.

- Calf sheds need ample lighting. At least 10% of the roof area should be clear sheeting.

- Where artificial lighting is used, 50 lux is the threshold.

- Better performance and less disease is associated with a space allowance of 2-2.5m2/calf.

Table 1: Shed Design Problems

| Common Design Problems | Consequences | Recommendation |

|---|---|---|

| Inadequate roof pitch (<15%). | Air deflected downwards, leading to draughts. | Pitch of 22° recommended. |

| Inappropriate inlet location and poor design. | Reduced effectiveness and downward deflection of air. | Eave inlets are ideal, 1.8-2.5m above floor. Gable ends are less effective. |

| Space boarding restriction of inlet. | Inadequate flow of air across the house. | Ensure space boarding is not covering or obstructing inlets. |

| Spaces under doorways and pen divisions | Can cause low level draughts. | Reduce spaces, fill gaps. |

| Large height differences between inlets and floor. | Influences the pattern of airflow in windy conditions. Reduces the stack effect in calm conditions. | Have height difference of <3m between inlets and floor. |

| Obstruction of outlet. | Reduces effectiveness of ventilation. | Simple open ridge space works best. Make sure that capped ridge outlets are properly designed and constructed. |

| Buildings wider than 10m. | Makes it difficult to get an even airflow across the building as the roof pitch tends to be lower, creating poorer air circulation. | Can be overcome by using spaced roof sheets or raised roof sheets. |

| Poor site location. | Major impact on air flow. | Ensure shed is positioned at right angles to the prevailing wind. Use mechanical ventilation. |