18 November 2024

Grass the green gold

Ireland is renowned for its abundant grass growth. Not only is grass the main source of feed for pasture-based animals, Teagasc scientists have demonstrated its potential for use in a multitude of products from pharmaceuticals to packaging.

Photo credit: IvanMikhaylov/istockphoto.com

We are seeing demand for sustainable food protein sources skyrocket, driven by issues of an escalating global population, increased urbanisation, rising numbers of people affected by protein malnutrition, and stern environmental concerns. Demand for dairy, animal and fish proteins is rising constantly, and global demand for animal proteins is expected to double by 2050.

However, animal rearing is associated with high greenhouse gas (GHG) emissions and increased land and water usage, as well as recent concerns of increased health risks and ethical and religious disputes linked to animal slaughtering. Hence, the shift has been towards embracing alternative sources of protein.

Cultivating high-protein crops such as soy is resource-intensive, demanding significant water usage and a heavy reliance on fertilisers. Grass, on the other hand, grows almost anywhere and requires minimal water, fertiliser or pesticides. If cultivated, grass can be grown abundantly and harvested with relatively low costs. Using locally grown grass for protein production can reduce transportation costs and support local economies.

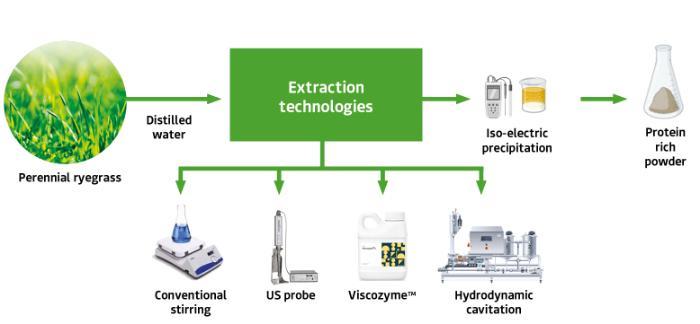

Extraction technologies for protein recovery from perennial ryegrass. Image credit: Teagasc

From pasture to plate

Grass may be typically perceived as a low protein source varying in protein content between 16-28% when dried, compared to legumes having a protein content of 20% to 40% on an average. Freshly harvested grass, which contains nearly 80% moisture, has a much lower protein content of around 5% compared to its dried form. Grass also has a high content of complex and rigid polysaccharides, namely cellulose, hemicellulose and lignin. Rahel Suchintita Das, Research Officer at Teagasc Ashtown, explains that all these factors raise questions about the feasibility of extracting protein from grass.

“This is where our research outcomes offer a promising solution. At Ashtown’s Food Research Centre, we harvested perennial ryegrass and processed it directly for protein extraction. This allowed us to explore the possibilities of eliminating the need for energy-consuming pre-processing preservation steps, such as drying.”

The research team also aimed to develop a clean and green extraction process, switching from the use of harsh and detrimental chemical solvents to simple plain water as the solvent for extraction. To achieve this, they efficiently leveraged the cutting-edge technologies of ultrasonic cavitation at lab scale and hydrodynamic cavitation at the pilot scale. This allowed them to mechanically break down the cell walls, along with the tough polysaccharide network in the grass tissues, to help extract the protein in water.

“We also explored the potential of a multi-enzyme blend to hydrolyse the polysaccharides and loosen the matrix to enable enhanced protein diffusion. The proteins solubilised in water were recovered by iso-electric precipitation technique,” Rahel continues.

Ultrasonic cavitation for 20 minutes delivered 53% protein content, hydrodynamic cavitation for 30 minutes yielded 47% protein content and enzymatic hydrolysis for 3 hours resulted in 61% protein content in the final protein product. In contrast, a conventional method of only mechanical stirring led to 56% protein content in the precipitate in 18 hours.

Extraction technologies implemented for protein recovery from perennial ryegrass. Photo credit: Teagasc

A zero-waste approach

Rahel explains that the resultant proteins, obtained through extraction using the advanced techniques, displayed a beneficial amino acid profile and significant water and oil-holding capacities along with noteworthy emulsification and foaming properties: “Exploiting these properties opens the door to using grass proteins in formulating a variety of food, feed, nutraceuticals, pharmaceuticals, cosmeceuticals and also biodegradable packaging materials.”

Potential high-value products include: alternative protein based milks, yoghurts, spreads, cheese; bakery and extruded products; salad dressings; protein shakes; protein-rich snacks; ready-to-prepare mixes; as binders, extenders and fillers in meat-based products and meat analogues; and films, gels and encapsulates.

Rahel adds that this research has implications beyond directly developing products containing grass proteins. “The solid biomass residue remaining after protein extraction is being targeted towards further use in recovering dietary fibre. The liquid waste streams are being investigated as substrates for microbial propagation and fermentation to produce bioactive compounds, micro-nutrients and bio-stimulants.”

Ultimately, this cascading approach for complete utilisation of the grass and its processing side streams holistically paves the way for the creation of a zero-waste sustainable bio-refinery, she concludes.

“So, next time you’re lying in a field, contemplate this: beneath you is a sustainable, nutritious, and downright revolutionary protein source. It’s time to think outside the (cereal) box and identify the green gold. Embrace it, and you might just find the future of food under your feet.”

Funding

UCD Ad Astra Fellowship and U-Protein.

Contributors

Rahel Suchintita Das, Research Officer, Teagasc Ashtown/University College, Dublin.

Marco Garcia-Vaquero, Director of Food Science Programme, University College Dublin.

Brijesh K. Tiwari, Principal Research Officer, Teagasc Ashtown.

brijesh.tiwari@teagasc.ie