21 February 2025

Turning waste into wealth: the hidden potential of animal blood proteins

Animal blood is a nutrient-rich by-product offering sustainable solutions. Innovative processes transform it into valuable products, turning waste into wealth and advancing a circular economy.

Credit: MediaProduction/istockphoto.com

Ireland has established itself as a leader in sustainable practices within the meat processing industry. Among the many valuable outputs of this sector, animal blood has emerged as a promising yet underutilised resource. Recent advancements have highlighted its potential in creating high-value applications across the food, nutraceutical and pharmaceutical sectors, offering innovative pathways to sustainability and economic growth.

Animal blood as a sustainable resource

“Animal blood is a unique resource with immense potential,” explains Soudabeh Ghalamara, Postdoctoral Researcher at Teagasc Food Research Centre. “It is not only nutrient-rich but also aligns perfectly with circular economy principles, turning what was once considered waste into valuable high-end products.”

Environmental concerns demand greater resource optimisation in the meat industry. With global consumption of animal proteins expected to double by 2050, there is an urgent need for sustainable alternatives. Unlike traditional protein sources that require significant water, land and fertilisers, animal blood is an efficient, ready-made by-product.

“This approach enables the industry to support local economies while reducing reliance on synthetic additives,” adds Shay Hannon, National Prepared Consumer Food Centre Manager. By leveraging advanced processing technologies, the untapped potential of animal blood can be harnessed to produce bioactive peptides with applications in food and pharmaceuticals.

Soudabeh Ghalamara examines biorefinery processes in the labs at Teagasc Ashtown’s Food Research Centre. Credit: Teagasc

From slaughterhouse to sustainability

The meat processing industry generates substantial volumes of by-products, including animal blood, which has long been underutilised despite its immense potential. “Blood is often treated as waste, but it’s actually one of the most nutrient-dense outputs of meat processing,” explains Brijesh K. Tiwari, Principal Research Officer. “Bovine blood, for example, contains up to 18% protein in its raw state, and these proteins have exceptional functional and bioactive properties.”

The composition of blood includes key proteins like albumin, globulins, and hemoglobin, which make it an ideal candidate for high-value applications in the food, nutraceutical, and cosmetic industries. However, its highly perishable nature and complex composition present challenges for recovery and utilisation. Additionally, with blood consisting of approximately 80% water, sustainable water management becomes a critical consideration in processing.

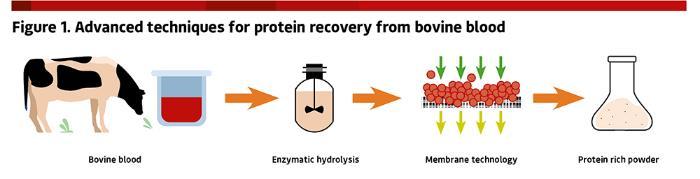

To address these challenges, researchers at Teagasc developed an innovative biorefinery approach to valorise bovine blood. This process begins with enzymatic hydrolysis, a method that uses enzymes to break down proteins into smaller, more functional peptides.

“A degree of hydrolysis (DH) measures the extent to which proteins are broken down into smaller peptide chains – and this process achieved a DH of 45%,” explains Soudabeh. “A higher DH is significant for generating bioactive peptides, which possess enhanced functional properties like antioxidant and antimicrobial activity.”

Following hydrolysis, the peptide-rich fractions undergo membrane filtration, incorporating both microfiltration and ultrafiltration. This dual approach separates proteins and peptides based on molecular weight, producing fractions enriched with bioactive compounds.

“The resulting fractions exhibit antioxidant, antimicrobial and ACE-inhibitory activities, alongside exceptional functional properties such as solubility, water- and fat-binding capacities, and emulsifying abilities,” adds Soudabeh.

These fractions hold practical potential across various industries, from protein-enriched foods and bakery products to encapsulates for bioactives and cosmetics. By unlocking the hidden value of this by-product, the meat industry can significantly reduce waste, increase resource efficiency, and open new avenues for sustainability.

Figure 1: Advanced techniques for protein recovery from bovine blood

Towards a zero-waste biorefinery

“Creating a zero-waste biorefinery is the next big step for the meat industry,” says Brijesh. Solid by-products from blood can be used to make valuable products like iron supplements for nutrition or natural food colourants. Meanwhile, the liquid waste, which still contains nutrients, can be used in fermentation processes to produce useful items such as enzymes, bioactive compounds, and organic fertilisers.

“This step-by-step approach ensures that nothing goes to waste, and turns every part of bovine blood into something useful,” Shay notes.

By adopting these innovative methods, the meat industry can reduce waste, protect the environment, and lead the way towards a more sustainable and efficient future.

Funding

Department of Agriculture, Food, and the Marine (DAFM) and CirCoVal Project.

Contributors

Soudabeh Ghalamara, Postdoctoral Researcher, Teagasc Food Research Centre, Ashtown, Dublin.

Shay Hannon, National Prepared Consumer Food Centre Manager, Teagasc Food Research Centre, Ashtown, Dublin.

Brijesh K. Tiwari, Principal Research Officer, Teagasc Food Research Centre, Ashtown, Dublin. brijesh.tiwari@teagasc.ie