Future Beef Newsletter June 2025

Kay O’Sullivan

Kepak – Farm Update | Technical Update – Spreading protected urea | Technical Update – maximising second cut silage yields | Upcoming Events | Teagasc/ABP groups | Top Tips for June | The Beef Edge Podcast

Upcoming Events

- Sun 15th June: AgriAware Open Farm Day on Aonghusa Fahy’s farm, Ardrahan, Co. Galway

- Fri 25th July: Future Beef farm walk on Kay O’Sullivan’s farm, Mourenabbey, Mallow, Co. Cork

Boost profitability and protect your land: join the Future Beef/ABP discussion groups!

Photos from the first group meeting on Future Beef farmer John Pringle’s farm in Co. Wicklow

Teagasc’s Future Beef Programme and ABP Food Group invite you to join targeted discussion groups for Irish beef farmers who want to increase farm profits and reduce environmental impact – all with practical, proven advice.

What’s in it for you?

▶ Practical, on-farm solutions tested on demonstration farms;

▶ access to the latest research and cutting-edge agri-tech tailored for Irish conditions;

▶ tips to improve animal health, fertility, and overall herd performance;

▶ save time and money with smarter, efficient farming practices;

▶ learn how to reduce emissions and future-proof your farm for changing markets;

▶ chance to get one-on-one advice and mentoring from industry experts;

▶ potential access to grants and supports for sustainable beef production; and,

▶ influence the future of beef farming and policy by sharing your insights.

Join fellow progressive suckler to beef and store to beef farmers for discussions, demonstrations, and plenty of refreshments!

We are starting to form groups in Wexford and Kilkenny, with a view to covering all ABP Group strongholds by the end of the year.

Interested?

Contact Aideen Bates on 086-165 3501, or Eleanor Cummins on 086-816 5984 today to join the group!

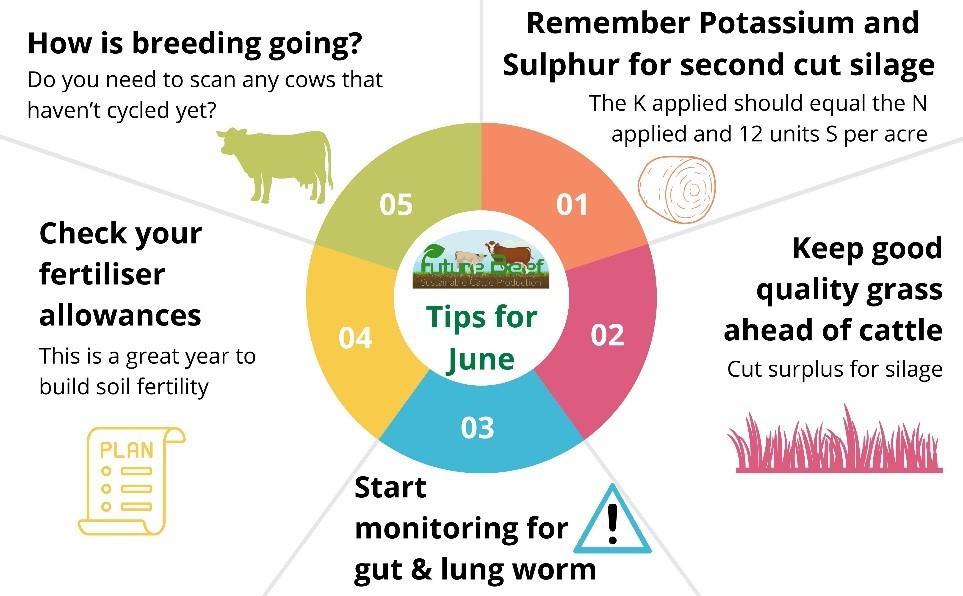

Top Tips for June

Farm Update – Kay O’Sullivan has improved herd fertility and has a focus on producing high-quality silage on her organic farm

Kay O’Sullivan

Kay is organically farming 63.2ha, including 11.16ha forestry. She farms the land herself and also makes use of hired labour. The soil type is a free-draining loam. She runs a spring-calving suckler to store/beef system, along with a lowland ewe system. The suckler herd comprises 25 cows and the ewe flock contains 75 ewes. Kay is now reducing the ewe numbers to 25 and increasing the cow numbers to 30. The cows are all bred to 100% AI, typically to pedigree Angus bulls. Some offspring are finished off redstart on the farm and others are sold live as yearlings.

Kay has placed a huge emphasis on improving herd fertility over the last number of years and this can be seen from her herd calving interval of and six-week calving rate of 83%. Going forward Kay would like to maintain herd fertility but also place a bigger emphasis on carcass weight and milk. Kay plans to use five Angus bulls evenly in 2025. The bulls chosen are Gabriel Pat 1949 (AA4631), Sallowglen Jamie T771 (AA4632), Swanky N257 Hardy (AA4633), Westellen Boss Y929 (AA9860), and Te Mania Nebo N424 (AA7452). This bull team will deliver 8.9kg for carcass weight, 6.6kg for milk, and -5.67 days for calving interval.

In order to achieve a high six-week calving rate as well as a high conception rate, Kay also requires a good three-week submission rate in her herd. She records cows coming into heat pre breeding, and uses these records along with timely observations to identify cows suitable for AI. Recording these pre-breeding heats allows Kay to submit cows for AI with more confidence, especially if for any reason a cow doesn’t show a strong heat.

Producing high-quality silage is very important in Kay’s organic system, as all beef animals are finished off forage as grass, grass silage or redstart. No concentrate is fed to cattle at any stage of their life. The first cut was made on May 2 before grass headed out. High DMD (75%) red clover silage is used to supplement both growing and finishing animals. Kay grew 11 tonnes DM per ha in 2024, and uses weekly farm grass walks to identify both surpluses and deficits using Pasture Base. Underperforming paddocks are identified for reseeding with a suitable multispecies mix in order to maximise forage growth. For further information on Kay’s farm, watch the video below and click on ‘Read more’.

Farm Update: Less Stress Means More Success on Kepak’s Farm in Caulstown, Co. Meath

Finishing cattle in a shed on the Kepak farm

The Kepak team understands the science behind stress and how it impacts animal welfare and productivity. Elevated cortisol levels don’t just affect cattle behaviour – they suppress immunity, leaving livestock more vulnerable to disease.

The Solution: Calm Environments and Structured Protocols

Kepak’s answer to this challenge, overseen by farm manager Sam Myles, is a combination of:

- A quiet environment

- Consistent handling

- A structured 24-hour rest period before any interventions

This initial “cooling-off” window allows animals to recover from transport stress, helping cortisol levels to fall and ensuring vaccination programmes are more effective.

Vaccination: A Carefully Planned Protocol

Vaccination begins the day after animals arrive, with each one receiving the same carefully planned protocol:

- Intranasal RSV and Pi3 Vaccine

These are common respiratory viruses in Irish cattle.

- Frank O Sullivan, vet to the Kepak farm, and Kieran O’Mahony, Area Veterinary Manager at Zoetis, demonstrated the correct use of the applicator.

- The broad mist delivers droplets deep into the nasal passages – the typical entry point for viruses.

- This method offers rapid, localised immunity – just five days for RSV – and works faster than traditional injectable vaccines.

- As animals often come from different sources, the risk of introducing IBR is high.

- A single intramuscular shot provides protection for six months.

- Targets diseases like blackleg and tetanus, essential for herd protection.

Targeted Parasite Control

Parasite treatments at Kepak are not given routinely. Instead, decisions are based on:

- Faecal testing

- Thrive rates

- Factory reports

This targeted approach avoids unnecessary treatments and supports more sustainable management.

Housing That Promotes Calm

After vaccination, cattle are housed in small, stable groups. These are designed to:

- Prevent hierarchy struggles and bullying

- Reduce stress and support immune function

Animals remain in the same group and same pen for the entire finishing period.

Results That Speak Volumes

As we toured the farm, one thing stood out: the calmness and contentment of the cattle.

This calm environment has led to:

- A dramatic drop in antibiotic use

- Reduced incidence of subclinical disease

- Better weight gain

- Improved feed efficiency

- Lower mortality rates

A Model for the Future

With increasing pressure to reduce antibiotic use and improve animal welfare, Kepak’s Caulstown model offers a clear message.

Technical Update – Spreading Protected Urea on Grassland – Key Advice for Irish Farmers (2025)

By Dermot Forristal, Teagasc

Protected urea is an effective nitrogen source for grassland, but it needs careful spreading for best results. Due to its lower density (0.75 kg/L vs. 1.0–1.2 for other fertilisers), protected urea spreads differently and often requires different settings or narrower bout widths.

Key spreading tips for Irish farms:

- Machine Settings: Always check your fertiliser spreader settings. You need both accurate rate calibration and even distribution. Poor spreading wastes nitrogen—even if striping isn’t visible.

- Buy Quality Urea: Choose products with strong, large granules (90% in the 2–4mm+ range, crush strength >5kg).

- Use Manufacturer Guidance: Good spreaders come with setting data or app support to match fertiliser type. Use this to adjust vane position, disc speed, tilt angle, or drop point.

- Check Spread Pattern: Use tray tests if possible. If no data or trays are available, reduce bout width to ~70% (e.g. from 18m to 12m).

- Avoid Urea Blends: Blends can spread unevenly due to different particle weights. If using them, use narrow bout widths.

- Maintain Equipment: Ensure discs, vanes, and spouts are clean and undamaged.

- Single Disc Spreaders (e.g. quads): Drive in the same direction around the field to avoid poor patterns. Constant speed and proper setup are essential.

- GPS Helps: Simple GPS units help maintain accurate tramlines and bout widths.

Read more here.

Technical Update – Maximise Your Second Cut Silage Yields This Summer

Mark Plunkett, Training and Development Specialist with the Signpost Programme, shares the best fertiliser strategy for second cut silage this year to help rebuild silage stocks.

Silage season is well underway

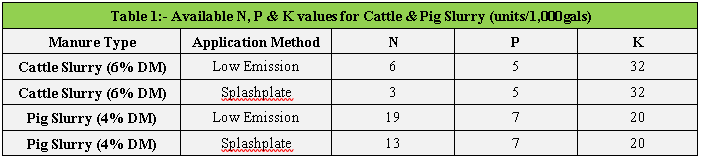

- Use Cattle Slurry to Save on Fertiliser

Cattle slurry is a valuable source of Phosphorus (P) and Potassium (K)—essential for grass regrowth. It also supplies Nitrogen (N), especially when applied using Low Emission Slurry Spreading (LESS) systems, which boost N availability by up to 3 extra units per 1,000 gallons and reduce ammonia losses.

- Fertilise Based on Yield Targets

Tailor fertiliser rates to expected yields:

- 4t fresh grass/ac (2t DM/ha): 40 units N, 6 units P, 40 units K, 6 units S per acre

→ Apply 2 bags/ac 15-3-20 +S +0.2 bags of pro urea/acre or 1,500 gals/ac slurry + 0.8 bags Protected Urea +S - 8t fresh grass/ac (4t DM/ha): 80 units N, 13 units P, 80 units K, 12 units S per acre

→ Apply 4 bags/ac 15-3-20 +S + 0.4 bags of pro urea/acre or 2,500 gals/ac slurry + 1.7 bags Protected Urea +S

- Don’t Forget Sulphur

Apply 6–12 units of Sulphur per acre to support grass dry matter yield and nitrogen efficiency.

Proper planning for your second cut silage—using slurry and the right fertiliser mix—can help maximise yields, reduce costs, and protect soil fertility.

You can read more here.

The Beef Edge Podcast

Keep up to date on all things beef on The Beef Edge Podcast weekly.