February 2026 Future Beef Newsletter

Sign up to receive the Teagasc Future Beef Newsletter

Technical Updates: Calving Countdown: Are You Ready? | Protect the Naval, Protect the Calf | Preparation for Calving Webinars

Farm Updates: James Skehan – Getting the Basics Right at Calving | Cathal Irwin – Small Changes Making a Big Difference to Finishing Cattle

Top Tips | The Beef Edge Podcast

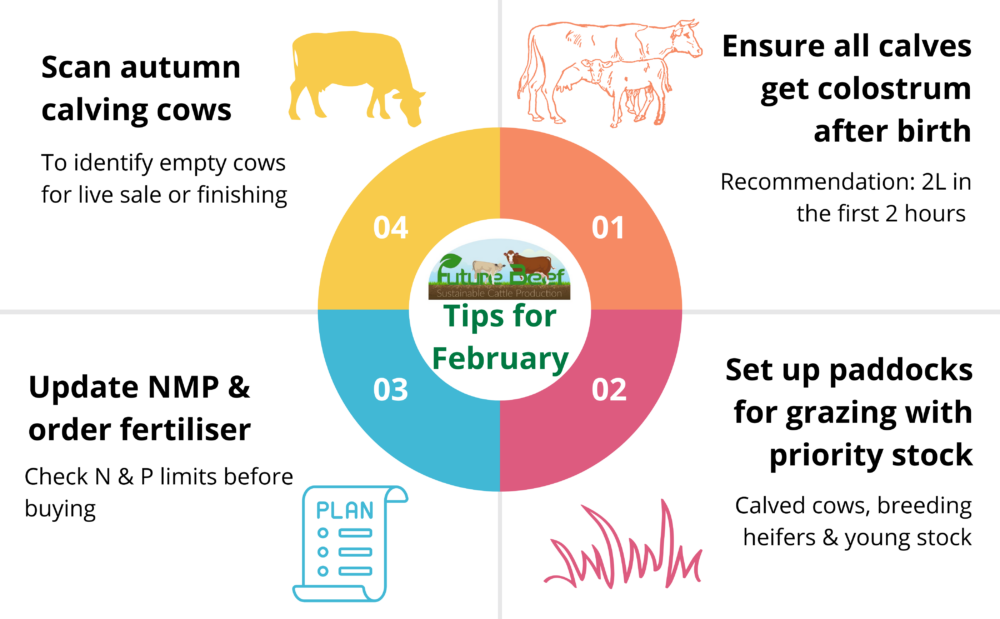

Top Tips for February

Technical Update – Calving Countdown: Are You Ready?

Use the calving checklist to help prepare for the calving season

- Preparation is essential: Use the ICBF calving report to plan labour, facilities and calving supervision, particularly for heifers and twin-bearing cows.

- Dry cow nutrition supports easier calving: Feeding a high-quality dry cow mineral for at least six weeks pre-calving helps reduce milk fever, retained placentas and weak calves on suckler farms.

- Vaccination improves calf immunity: Strategic cow vaccination against scour and respiratory disease, where appropriate, enhances colostrum quality and early calf health.

- Good hygiene reduces disease risk: Keep cows clean, maintain well-bedded calving pens and practise strict hygiene to minimise infection and scour in newborn calves.

- A complete calving kit is vital: Essential calving equipment includes calving ropes, lubricant, calving jack, iodine for navel disinfection, stomach tube or bottle, thermometer and calcium or magnesium supplements.

- Colostrum is critical for calf survival: Ensure every calf receives sufficient high-quality colostrum as soon as possible after birth; frozen colostrum should be available as a backup.

- Correct calving observation prevents losses: Monitor cows closely but intervene only when necessary and at the correct time to avoid injury or stress.

- Strong early calf care boosts profitability: Prompt navel care, warmth, suckling checks and early problem detection improve calf health, suckler herd performance and farm profitability.

A printable checklist for calving is available here.

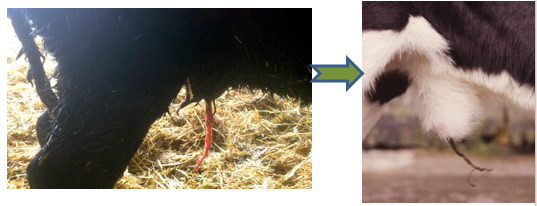

Technical Update – Protect the Navel, Protect the Calf

Infections can enter through a calf’s naval if not properly protected

The following steps will help to reduce navel ill, support calf immunity and improve overall calf health on farm:

- Clean housing reduces navel ill risk – Keep calving pens, loose housing and slatted areas clean, dry and well-bedded with lime and fresh straw to minimise harmful bacteria exposure to newborn calves.

- Clean cows help prevent infection – Trim dirty cows’ tails/flanks before calving and move them into clean calving pens 2–3 days before calving so calves avoid dirt at first suckling.

- Clean farmer practices matter – Wear clean overalls or disposable gear, wash hands thoroughly and disinfect equipment when handling calves to avoid introducing infection.

- Navel dipping/spraying protects calves – Apply a 7–10% iodine or chlorhexidine navel dip/spray within 15 minutes of birth (and again 1–2 hours later) to disinfect and promote quick drying and closure of the cord.

- Colostrum timing is crucial – Feed high-quality colostrum early; aim for 2 litres within 2 hours of birth so antibodies are absorbed before gut closure begins.

- Monitor navels for problems – Check calves regularly; enlarged, painful or pus-discharging navels may indicate navel ill and require veterinary treatment.

You can read more here.

Did you miss our ‘Preparation for Calving’ webinars? Watch back here.

- Reducing calf losses before they happen through body condition scoring cows, pre-calving minerals & vaccinations.

- Calving the cow and keeping the calf alive by managing difficult calvings, having safe calving facilities and calf care after birth.

Farm Update: James Skehan – Getting the Basics Right at Calving

James is pictured with his wife Joanne and their two children Macarton and Nellie

James Skehan farms 72 acres in O’Briensbridge, Co. Clare, operating across three separate land blocks. He runs a spring-calving suckler herd of 28 cows, selling male progeny as 18-month-old stores. Surplus heifers not required for breeding are also sold as stores.

A compact calving system is central to the farm’s operation, with approximately 66% of the herd bred through AI and the remaining cows served by a high terminal-index Limousin stock bull. AI sires used to generate replacements (CH5980, SI4350, SI8520 and AA9860) have an average replacement index of €172, with strong emphasis placed on milk yield, fertility and carcass traits.

Two key performance indicators for a profitable suckler system are compact calving and the production of one healthy calf per cow per year. In 2025, 71% of cows calved within six weeks, with 0.91 calves weaned per cow. In 2026, the herd is set to calve over a nine-week period, with over 80% of cows expected to calve in the first six weeks.

In-calf heifers eating soya bean meal on the farm

Hygiene and preparation are key priorities in managing a compact calving system. To support calf health and performance, James places strong emphasis on dry cow nutrition and herd health in the lead-up to calving. All cows receive a high-quality pre-calver mineral, alongside a comprehensive vaccination programme to reduce the risk of calf scour.

Key management practices in place this spring include:

- Ensuring cows calve down in correct body condition

- Vaccinating cows against calf scour

- Feeding a high-quality pre-calver mineral

- Supplementing cows to enhance colostrum quality

- Thorough cleaning and disinfection of calving and calf-rearing facilities

- Having all calving equipment prepared and ready for use

James’s approach demonstrates how targeted management before calving can improve calf survival, herd performance and overall system profitability.

You can read more about his farm here.

Watch the video below where he outlines his preparations for calving.

Farm Update: Cathal Irwin – Small Changes Making a Big Difference to Finishing Cattle

Cathal Irwin

Cathal is an Irish suckler beef farmer operating an 18.8 ha farm outside Castlebar, Co. Mayo, running a 20-cow spring-calving suckler system. All male calves are finished as bulls under 16 months of age, while heifers are sold as stores.

Some of the finishing bulls on slats

He is currently feeding 9 home bred bulls and 14 bought in bulls for finishing under 16 months of age. This year Cathal has made changes on his farm and the lifetime average daily gains of the bulls are averaging 1.31kg/day for his home bred bulls and 1.44kg/day for the bought in bulls, which is 0.2kg/day ahead of last year. He has done the following to achieve this:

- Diet: Creep fed weanling bulls before housing.

- Parasites: All bulls were dosed for stomach worms, lung worms, lice, rumen fluke and liver fluke at housing.

- Vaccines: All bulls were vaccinated against IBR, RSV, Pi3 and mannheimia.

- Nutrition: The bulls were gradually built up on ration from 2-3kg/head/day to 8-9kg/head/day. They are getting this in 2 splits, i.e. 4-4.5kg in the morning and 4-4.5kg in the evening, along with ad lib access to good quality silage.

- Shed environment: Cathal replaced the mats in the slatted shed for extra comfort for the bulls. There is also stock board between them and the heifer pen to help separate them. Sheeting has been adjusted in the straw bedded area to allow for better ventilation.

- Lying space: The bulls have 2.96m2 lying space on the slats (2.7m2 recommended) and 5.95m2 lying space on the straw area (4m2 recommended) which is more than adequate.

- Feeding space: The minimum feed space required for finishing cattle getting ration is 0.65m/head and this is also available for all bulls.

Bulls can be fed on both sides of the pen to maximise feed space

- Water: Cathal is in the process of upgrading the water troughs in the shed to keep water cleaner and more accessible.

- Monitoring weights: The bulls are weighed very 4-6 weeks to monitor weight gains and ensure they are still performing well. This will help Cathal to draft cattle as they come fit for the factory and with weights raging from 294kg to 648kg on 27th December, he expects to be selling the first few over the coming weeks.

You can read more about Cathal’s farm here.

The Beef Edge Podcast

Keep up to date on all things beef on The Beef Edge Podcast weekly.